Ductile Iron Water Pipe

CCMCO has joined forces with other experts in the Ductile Iron Pipe Production Sphere to form a strategic partnership, CIZSA, in order to provide our customers with a customer experience that is not currently available in the market. CIZSA Directors have worked in pipe plants consistently for decades, supplying machinery and finishing lines for DISP producers.

Currently, CCMCO co-owner, and CIZSA director, Will McKee, is considered to be an expert in the area of Ductile Iron Pipe production. His involvement with DISP projects offers a strategic advantage to our customers. Our alliance also includes Volker Ziegenbein, Principal of Ziegenbein Engineering, the engineering firm that has worked on Bracker and Fritz Werner machinery designs.

CIZSA has the technology and know-how to develop the complete facility, from basic engineering and iron chemistry, to casting machines to finishing line equipment and beyond.

- Induction Melting and Holding

- Mg Treatment

- Core Room & Core boxes

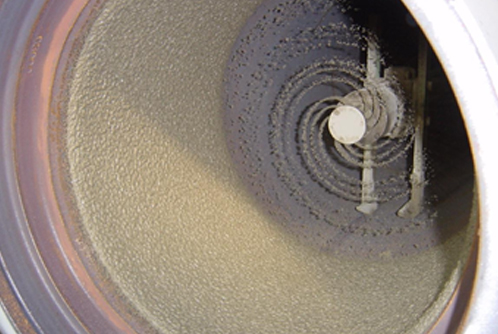

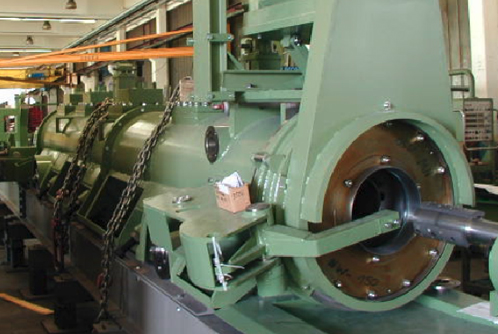

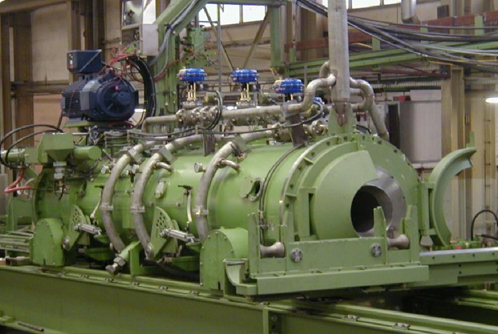

- Casting Machines

- Pipe Handling Equipment

- Bell Clean Out and Inspection Area

- Annealing Furnaces

- Laboratory

- ID Grinding

- Ovality Correction

- Cement Lining and Curing

- Bitumen Coating and Drying

- Marking

- Bundling

- Mold maintenance

- Straightness Inspection and Correction

- Cutoff

- Chamfering

- Zinc Coating

- Hydrostatic Pressure Testing

CIZSA uses a DIP production process that is proven to provide the highest yield and minimal material usage. This process is not known to the Chinese competition, but it is the method used by Europeans and US manufacturers. This process results in longer mold life, lower energy usage, lower scrap rates, process control that enables thin wall DIP and consistent wall thickness. All of this results in customer competitiveness.

- Guaranteed Scrap Rate: 2%

- Guaranteed Minimum required wall thickness on C Class pipes, per EN545.

- C40 Class pipe for 80-300mm

- C30 Class for 350-600mm

- C25 Class for 700-1000mm

- C20 Class for 1100mm-2000mm

Possible production rates for Pressure Pipe C40 through C20 with 100% machinery optimization with fully trained and experienced personnel:

- 90pc/hr for 100mm C40

- 20pc/hr for 1200mm C20

- Guaranteed Production Rates for C Class Pipes:

- 65pc/hr for 100mm Pressure Class C40

- 15 pc/hr for 1200mm Pressure Class C20

Possible production rates for Pressure Pipe C40 through C20 with 100% machinery optimization with fully trained and experienced personnel:

- 85pc/hr for 100mm K9

- 17pc/hr for 1200mm K9

- Guaranteed Production Rates for K9 Pipes:

- 70pc/hr for 100mm K9

- 12pc/hr for 1200mm K9

The information on the following pages was supplied by the report, Global Ductile Iron Pipe Market, compiled by PMR Solution.

The global DISP market “is expected to garner USD$13,627.3 Million by the end of 2030. The global demand for ductile iron pipe is increasing on the back of growing demand in developing nations, and growing investments by government towards sanitation and potable water supply. (PMR Pg. 19)“

“Asia Pacific is slated to account for a leading share of 50.3% by 2030 in the ductile iron pipe market. In Asia Pacific, huge demand for ductile iron pipe products is generated from China. Moreover, India and Southeast Asia is anticipated to witness lucrative growth in the years ahead on the account of rapid urbanization and industrialization coupled with focus towards changing the aging water infrastructure. (19)“

Governments of various nations are taking initiatives to meet the rising demand for water. Rapid urbanization in developing nations has significantly swollen the demand for infrastructure services such as roads, transportation, electric and power supply, water supply and sanitation. Moreover, the demand for ductile iron pipes for wastewater treatment has also increased to a rise in migration rate of the population towards urban centers.

Unsafe sanitation is one of the major concerns for governments across the globe. Along with rising population, it is becoming a more serious concern. According to the World Health Organization (WHO), more than half of the global population, i.e. Almost 4.5 billion people, still practice open defecation or use unsafe sanitary facilities and services. To control open defecation, governments across the world are undertaking measures for water sanitation. We anticipate that this factor will bolster the growth of the market worldwide.

Contact us today to learn more about CIZSA’s Services and Machine Offerings.