Equipment Extras

CCMCO offers a host of "extras" to customers for increasing process control. These auxiliary items can help increase production rates and reduce scrap.

Mold Coating Equipment

“Effective Mold Coating application is one of the single most important factors in achieving casting quality and yet it is an operation that is often performed without the consideration it deserves.”

CCMCO offers highly adjustable and effective automatic mold wash application devices

Applying mold coating automatically rather than manually offers some very clear benefits:

- Automatic spraying can be performed in less time with more consistent and uniform thickness than manual spraying.

- Casting surface finish can be varied to meet certain specifications by adjusting the speed of the lance and the number of passes.

These machines can be included with your machine purchase, or can be added as an aftermarket item. Features include:

- Single or Multi-Pass Programmability.

- Use with flood or air atomized type spray tips.

- Supplied with pushbutton or touchscreen technology.

- Manual or Automatic control of passes.

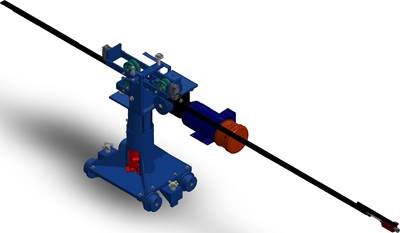

AR-17

The AR- 17 is a floor mounted unit with traversing spray lance, adjustable variable speed lance control, Manual vertical lance height adjustment. Optional transfer car available.

| Minimum Mold Diameter | Maximum Mold Length | ||

|---|---|---|---|

| Imperial | Metric | Imperial | Metric |

| 3" | 76mm | 84" | 2133mm |

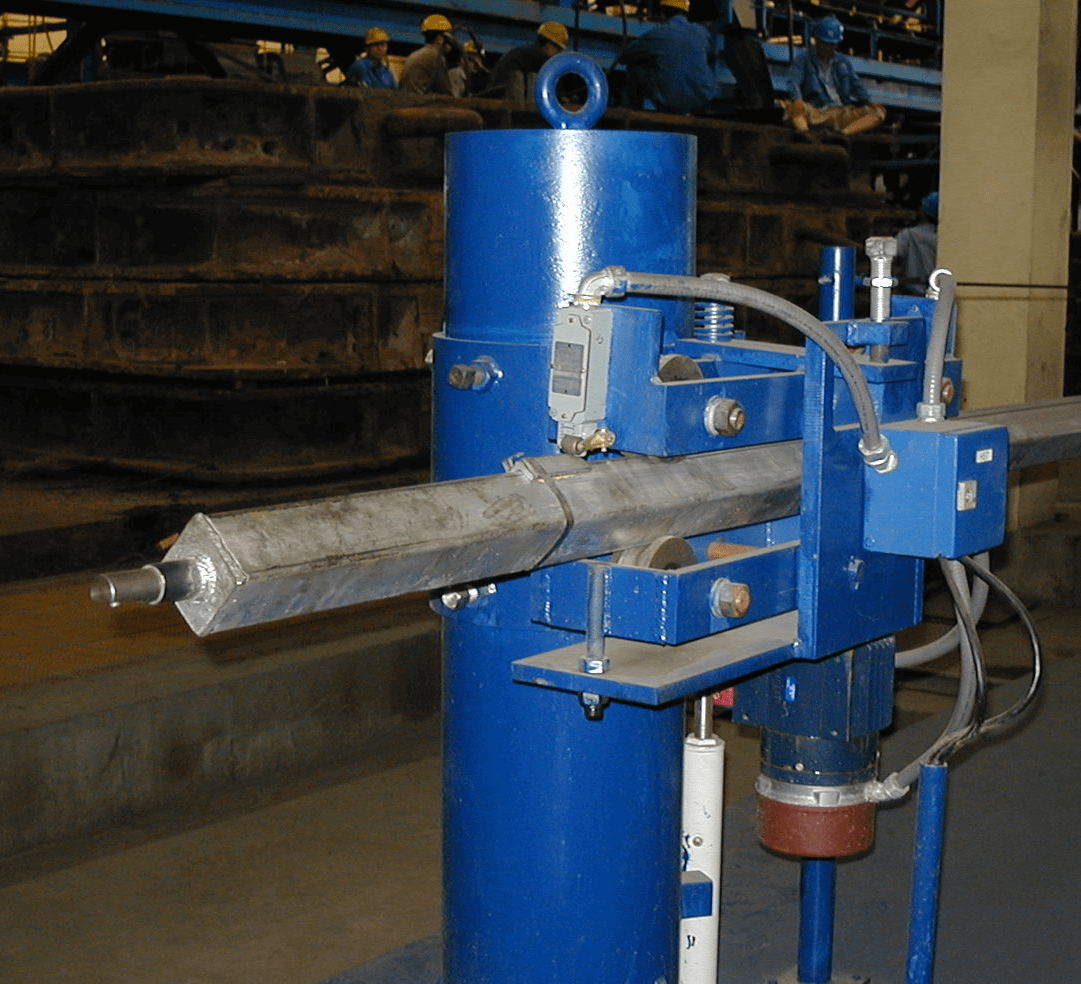

RH-20

The RH - 20 is a floor mounted unit with traversing spray lance, adjustable variable speed lance control, and Manual vertical lance height adjustment. Optional transfer car available.

It is a heavy-duty coating machine that is often supplied as a standard feature for CCMCO Model K and Model H series machine.

RH-20AS

The RH-20AS has the same features as the RH-20 but is supplied as a dual lance system with a coating lance and a cleaning lance.

| Minimum Mold Diameter | Maximum Mold Length | ||

|---|---|---|---|

| Imperial | Metric | Imperial | Metric |

| 4" | 100mm | 156" | 3,962mm |

| 5" | 127mm | 192" | 4,877mm |

| 6" | 153mm | 240" | 6,096mm |

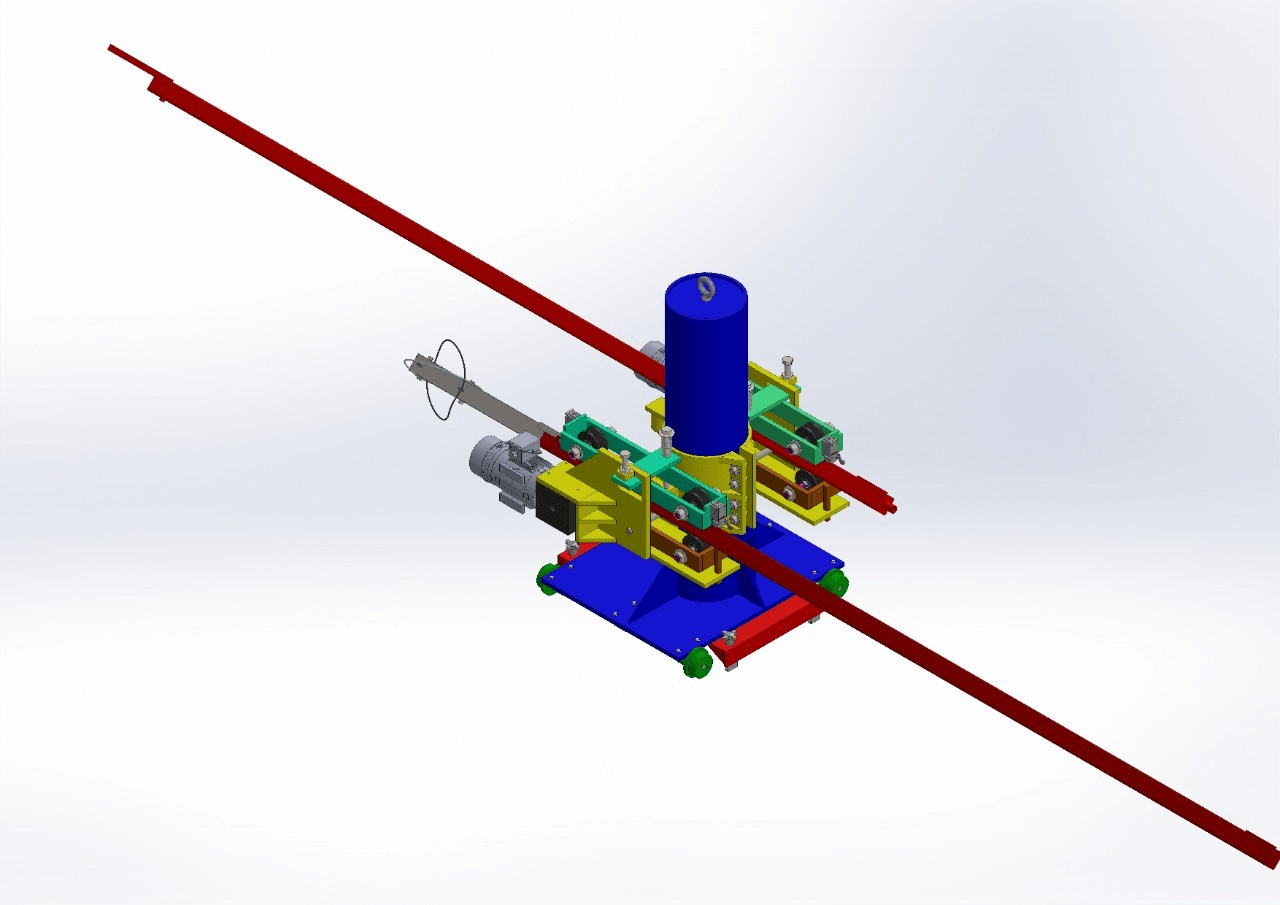

ASA-20

The ASA-20 is a traversing spray car assembly with variable speed controls and manual vertical lance height adjustment. This system was designed for smaller ID x longer length castings.

| Minimum Mold Diameter | Maximum Mold Length | ||

|---|---|---|---|

| Imperial | Metric | Imperial | Metric |

| 2 3/8" | 60mm | 120" | 3,048mm |

| 3 1/8" | 80mm | 197" | 5,000mm |

| 4" | 100mm | 240" | 6,096mm |

Automatic Mold Coating is not just for Horizontal Casting Applications!

CCMCO’s VACA design is designed to automatically apply coating in pit mounted vertical applications.

In order to meet the increasing demand to apply coating to long length and smaller diameter molds, CCMCO offers engineered solutions to meet our customer’s specific needs.Contact Us to discuss your requirements.

CCMCO offers a few different options for adding the customer's flux automatically to the spinning mold.

We offer the ability to spray the flux inside your spinning mold, or dump it using a trough. Both solutions remove the need for an operator to toss the flux in the spinning mold by hand.

Flux application can be supplied alongside spray coating and mold cleaning.

CCMCO's selection of Exothermic Blasters are pressurized vessels that can blow a variety of exthermic sizes into a spinning mold. The blaster can also be attached to ta lance and be used that way to blow flux into a spinning mold while the lance moves along the length of the spinning mold.

| Model | Melt Capacity |

|---|---|

| E300 Request Quote |

250# (113KGS.) MELT CAPACITY |

| E600 Request Quote |

500# (226KGS.) MELT CAPACITY |

| E1000 Request Quote |

1000# (453KGS.) MELT CAPACITY |

| E2000 Request Quote |

1500# (680KGS.) MELT CAPACITY |

| CUSTOM SIZED BLASTER | BLASTER WILL BE CUSTOM SIZED TO MEET CUSTOMER NEEDS |

| EXOTHERMIC BLASTER INTEGRATION WITH CENTRIFUGAL CASTING MACHINE | THIS ENGINEERED SYSTEM CAN BE SOLD FOR ANY SIZE BABBITTING MACHINE |

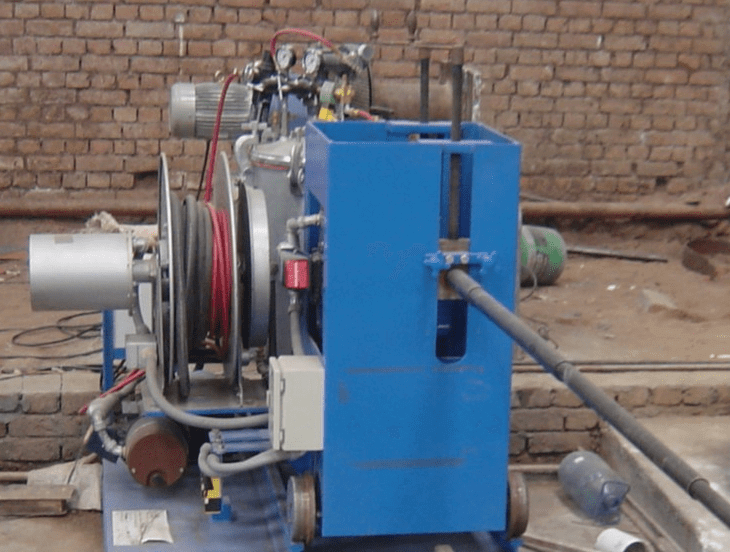

Casting extraction is one of the seven critical operations for producing quality castings. CCMCO supplies a variety of extraction solutions ranging from manual to automatic.

Several of our extraction solutions involve an appropriately sized winch and a casting support cart.

15 ton machine Casting Extraction cart with stationary foundation mounted winch (Not Shown).

2.5 Ton Machine Casting Support Cart with Integrated Winch

Fully Automated triple Cast Iron Soil Pipe Machine with ID grippers for extracting the casting.