Babbitt Room Solutions

|

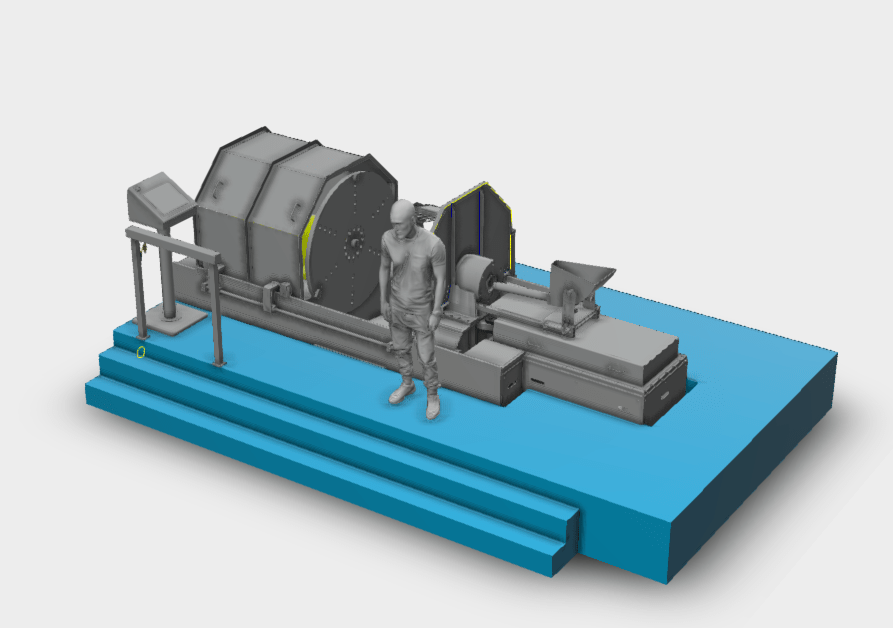

The Dual Faceplate machine for babbitting is an adjustable position machine where a bearing shell is clamped between two faceplates. This line of machines offers clients a solution for lining shells of many different diameter length combinations. CCMCO's Babbitt Lining machines are designed to line new Babbitt Bearings as well as re-Babbitt bearings using various grades of babbitting material. The machines in this series are capable of rotating both single piece and split shell type bearings. Economical to operate, these machines require no special foundations. Machine operators can be trained on the spinner without prior babbitting knowledge. Centrifugal casting of Babbitt Bearings produces high-quality bearings with a superior metallurgical structure, uniform wall thickness, and high material yield. Features of machines in this series include:

|

Model CBV

CCMCO's Model CBV line of vertically oriented babbitting machines are design and are a valuable addition to the babbitter's line up.

| Model | Bearing Size Minimum OD | Bearing Size Maximum OD | Bearing Height Maximum | Maximum Load | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Imperial | Metric | Imperial. | Metric | Imperial | Metric | Imperial | Metric | |||

| CBV-5-5 Request Quote | - | - | 2" | 51mm | 5" | 127mm | 5" | 127mm | 50lbs | 23kgs |

| CBV-8-8 Request Quote | - | - | 2" | 51mm | 8" | 203mm | 8" | 203mm | 50lbs | 23kgs |

| CBV-10-10 Request Quote | - | - | 2" | 51mm | 10" | 254mm | 10" | 254mm | 50lbs | 23kgs |

| Load Ratings are based on the combined weight of fixtures and bearing shell. | ||||||||||

Model CB

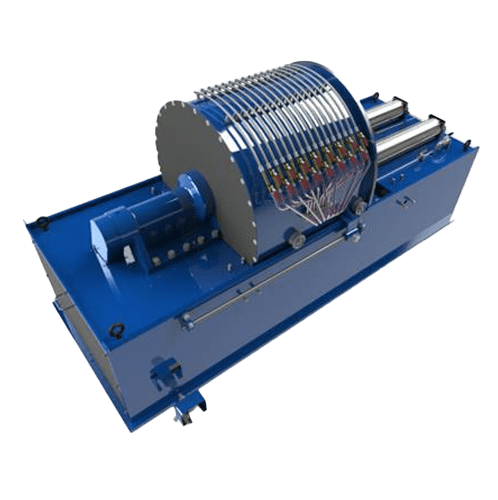

CCMCO's Model CB line of machinery has been in consistent production since 1969. This series of machines is chosen over and over again by major players in the Babbitting industry

| Model | Bearing Size Minimum OD |

Bearing Size Maximum OD |

Bearing Height Maximum | Maximum Load | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Imperial | Metric | Imperial. | Metric | Imperial | Metric | Imperial | Metric | |||

| CB-16-16-WC Request Quote | - | - | 4" | 102mm | 16" | 406mm | 16" | 406mm | 800lbs | 363kgs |

| CB-24-24-WC Request Quote | - | - | 4" | 102mm | 24" | 610mm | 24" | 610mm | 1,000lbs | 453kgs |

| CB-30-30-WC Request Quote | - | - | 4" | 102mm | 30" | 762mm | 30" | 762mm | 2,000lbs | 907kgs |

| CB-36-36-WC Request Quote | - | - | 4" | 102mm | 36" | 914mm | 30" | 914mm | 3,000lbs | 1361kgs |

| CB-45-45-WC Request Quote | - | - | 4" | 102mm | 45" | 1143mm | 45" | 1143mm | 4,000lbs | 1814kgs |

| Load Ratings are based on the combined weight of fixtures and bearing shell. | ||||||||||

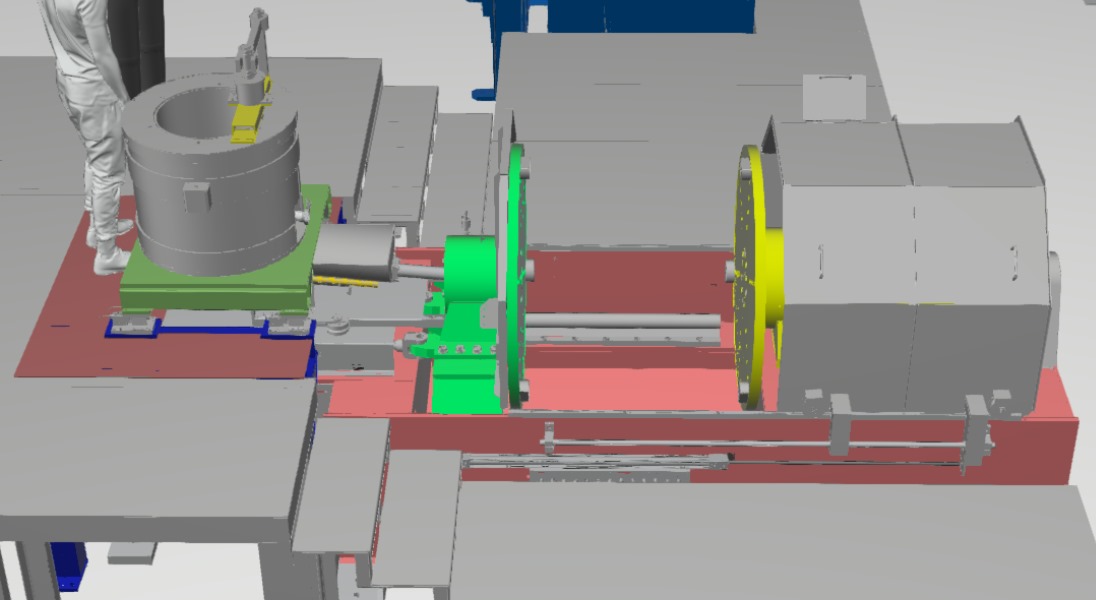

Model DB, 4 Ton Spin Load

CCMCO's Model DM is custom sized to meet customer requirements. It is designed specifically for heavy bearings. Common sizes are 45" (1143 mm) and up.

| Model | Bearing Size Minimum OD |

Bearing Size Maximum OD |

Bearing Height Maximum | Maximum Load | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Imperial | Metric | Imperial. | Metric | Imperial | Metric | Imperial | Metric | |||

| DB Request Quote | - | - | Custom Sized | Custom Sized | Custom Sized | 8,000lbs | 3,628kgs | |||

| Load Ratings are based on the combined weight of fixtures and bearing shell. | ||||||||||

|

Babbitt MeltersCCMCO offers a line of babbitt melters in different sizes. Melters can be stationary or tilting type and can be integrated in with your spinner, providing a seamless, repeatable pouring process.

|

Tin Pots

CCMCO offers tin pots in various sizes to meet customer requirements.

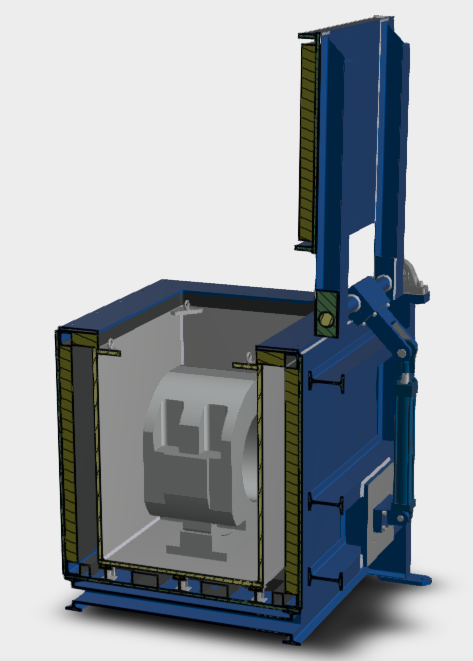

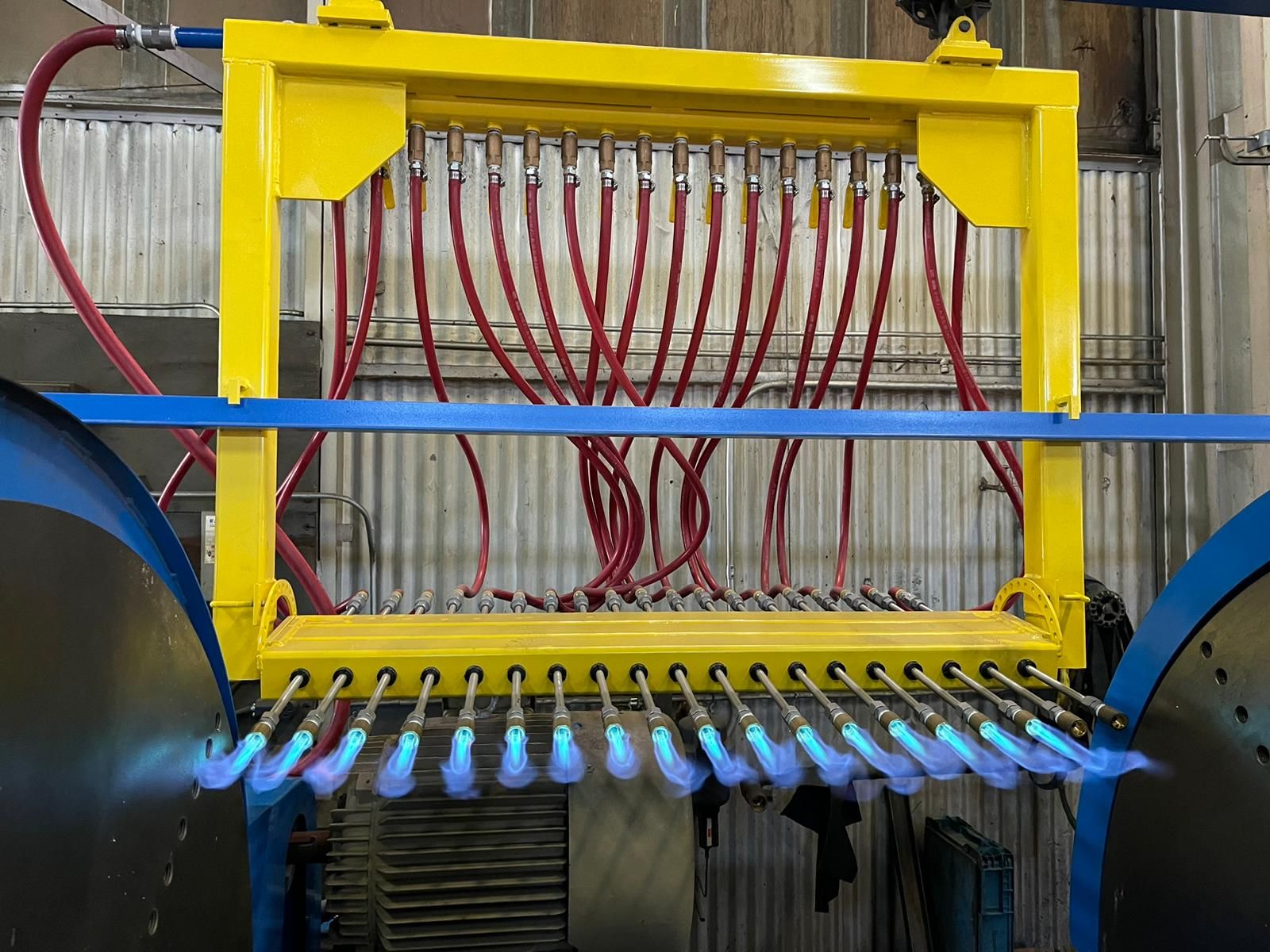

Shell Heating

Heating your shell to the correct temperature is an essential requirement for producing a quality part. Shells can be heated on or off the babbitt spinner. If heating on the spinner, a CCMCO shell heater offers an efficient heating solution:

Multivat Tank

Used for Model CB 24-24-WC and smaller, the MultiVat Tank can be used for cleaning and rinsing of bearing shells, acid pickling and tinning of the bearing shell before lining. The unit includes pneumatic aeration for degreaser, water rinse tanks and drain valves.

Pouring Automation

Clients can focus on operator safety and environment while achieving repeatable results through automating the Babbitt pouring process.

This engineered system includes a pouring platform, lift table for ease of loading melter, bottom draw babbitt melter, load cells for determining how much metal is available, servo driven stopper assembly for outputting specific amounts of Babbitt into the spinner.